When the machine used for earthmoving breaks down, what are the alternative solutions that the owner has?

Buying new construction machinery certainly has its advantages if you have the right budget.

When the budget is limited, you can repair the machine and, in the meantime, you can opt for a rental option. Repair can be done with new or recycled spare parts.

Many users do not like the idea of replacing their old machine with a new one, both for economic reasons and for reasons of difficulty in learning new technologies. If the operator uses the machine well and is productive, a repair is a good solution.

Some owners, for example, would choose to repair any component with the goal of maximizing the overall life expectancy of their machine.

Table of Contents

Repair of the machine: times and costs

The owner of a machine will surely have questions about the repair process. How long does it take? What kind of spare parts should be bought? New? Used? Compatible? How much it will cost? Although there are no definite answers, here are some tips:

What is the best moment to repair a machine?

Sometimes, a component breaks down. It may happen that there are some failing elements that are not vital for the operation of the machine and allow its operation. In order not to compromise the operation of the machine, it is necessary to replace the parts that do not work so as not to incur more serious and expensive failures. The failure of a component depends on the hours worked on the machine and the condition of the other major components.

Routine maintenance is very important. Examining fuel consumption, oil level and other routine operations are used to obtain information on the operation of the machine.

The operating conditions and uses of the machine are also to be considered. For example, the front end and transmission are used primarily in a wheel loader that is dedicated to extraction or loading and transport, rather than one used in a waste disposal station.

How long should I wait?

You need to consider several options:

What is the expectation after the repair? That is, how long do you want to keep the machine before replacing it? Will the machine be back in full-time operation or will it take on a support role and be a utility machine?

The role the machine plays in the job determines how much you are willing to spend time and money to repair it.

In most scenarios, larger machines are generally more advisable to repair due to the price of replacement parts than the price of a new machine.

Is the company ready for downtime during repairs?

It will be necessary to verify if there are pending works or if it is possible to use alternatives. If there are many jobs to fill and a lot of machines available, repair is a viable option. If there is a shortage of machines, you must find the parts as quickly as possible and proceed to repair it.

How much does it cost to repair a machine?

Repair costs vary in relation to the types of components to be replaced. In addition, if you do not have an in-house workshop, you also must add the hand-labour costs.

In relation to the budget, you can buy new and original or new but compatible or recycled spare parts from other machines.

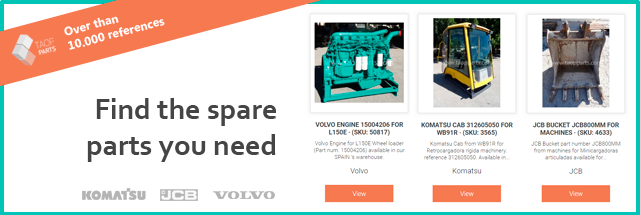

What can Taop Parts do?

Taop Parts acts when a customer has a machine with broken or defective components and underperforming. Our genuine recycled parts restore machine performance. Taop Parts has at its disposal a fleet of machines that it disassembles for the sale of spare parts. When a machine arrives, the technical department carries out general operational controls. Then the pieces are checked individually.

In case a machine repair is needed, the Taop Parts sales team can advise and find the best answers.

Link of interest