Valve timing on a diesel engine, such as the Komatsu SAA6D125E-5, is a critical procedure to maintain its optimal performance. This engine is mounted on Komatsu machines, such as the PC450LC-7 excavator, the WA480-6 loader or the HM300-2 articulated dumper. In this blog we will also address the verification of the axial play of the engine of this machine.

Komatsu SAA6D125E-5 Engine Valve Adjustment

1. Tools needed:

Before you begin, make sure you have the following tools on hand:

- Ratchet wrench: Useful for loosening and tightening valve nuts.

- Wrench and screwdriver set: To access the relevant engine parts.

- Calibration thickness gauge: Also known as gauges or calipers, it is used to measure the clearance between valves and camshafts.

- Torque wrench: Necessary to apply the correct force when tightening the valve nuts.

- Calibration Sheets: Provide precise specifications for valve adjustment.

- Engine service manual: contains precise information about the engine and manufacturer’s recommendations.

2. Preparation:

Locate the valves:

Identify the exhaust and intake valves on the engine. In the case of the SAA6D125E-5, this engine has 6 cylinders and 24 valves (12 exhaust and 12 intake).

Engine position:

Place the engine at the top dead center (TDC) of the number 1 cylinder. Consult your engine manual to find the reference mark on the crankshaft pulley.

What is an intake valve?

The intake valve is responsible for allowing the air-fuel mixture to enter the engine’s combustion chamber. During the intake phase of the engine cycle, this valve opens so that the mixture can enter and prepare for combustion.

What is an exhaust valve?

The exhaust valve, on the other hand, is responsible for expelling the burned gases resulting from combustion out of the combustion chamber. This valve opens during the exhaust phase of the engine cycle, allowing exhaust gases to be expelled through the exhaust manifold.

Main differences

- Function: The intake valve introduces the air-fuel mixture, while the exhaust valve expels the burned gases.

- Temperature: The exhaust valves support higher temperatures due to the hot combustion gases, reaching between 600º and 800º Celsius, while the intake valves handle lower temperatures, between 200º and 400º Celsius.

- Material: Exhaust valves are made of more heat-resistant materials, such as stainless steel alloys, to withstand high temperatures.

- Size: Intake valves are usually larger than exhaust valves to allow greater air intake and improve engine efficiency.

3. Measurement and Adjustment:

- Exhaust valves:

- Using the torque wrench, loosen the exhaust valve locknut.

- Use the feeler gauges or calipers to measure the clearance between the cam and the valve. Adjust if necessary.

- The recommended clearance for the exhaust valves is 0.71 mm

- Intake Valves:

- Repeat the same process for the intake valves.

- The recommended clearance for the intake valves is 0.33 mm

Tighten the locknut:

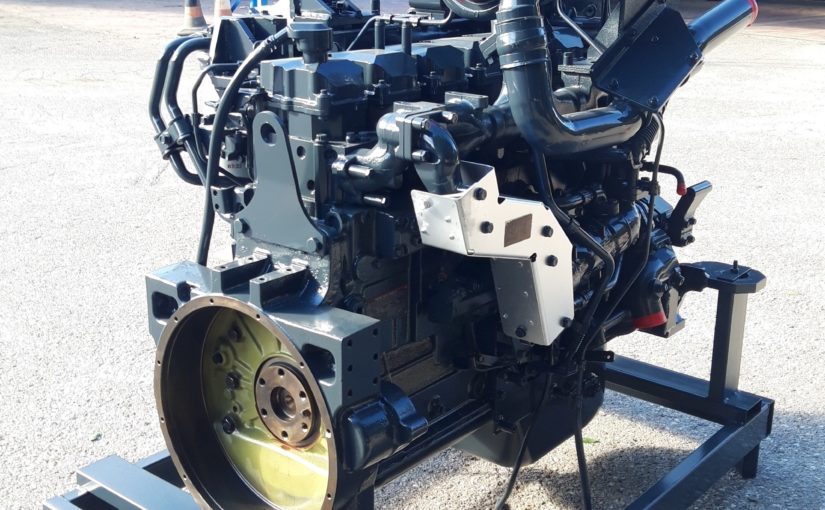

Once the valves are adjusted, tighten the locknut without moving the valve position. In the following image you can see a Taopparts mechanic carrying out this task.

4. Verification:

1. Turn the engine:

Crank the engine manually several times to ensure there is no interference between the valves and pistons.

2. Check again:

Remeasure the valves after cranking the entire engine.

Make sure all valves are within the specified range.

Valve timing has a significant impact on engine performance. Here are some of the ways it affects:

- Combustion Efficiency:

- The valves control the air intake and exhaust gas output. If the valves are not properly adjusted, the air-fuel mixture may be inadequate, which affects combustion efficiency.

- Power and Torque:

- Incorrect adjustment can affect engine power and torque. Valves that are too tight or too loose can decrease overall power and performance.

- Emissions:

- Valves influence emissions. If the exhaust valves are not closed properly, exhaust gas leaks may occur, increasing pollutant emissions.

- Noise and Vibration:

- Poorly adjusted valves can cause excessive noise and vibration. Proper adjustment helps reduce these discomforts.

- Engine Durability:

- Poorly adjusted valves can cause premature wear on engine components such as camshafts and valve guides.

In summary, accurate valve timing is essential for optimal performance of the Komatsu SAA6D125E-5 engine in terms of power, efficiency and durability.

How to Check Axial Play on a Komatsu SAA6D125E-5 Engine

Axial play refers to the lateral movement allowed between the rotating parts of the engine. In the case of the Komatsu SAA6D125E-5 engine, it is important to check it to ensure optimal operation. Follow these steps:

- Preparation:

- Make sure you have access to the specific service manual for the SAA6D125E-5 engine

- Top Dead Center (TDC) Location:

- Crank the engine manually until the number 1 cylinder reaches top dead center (TDC). Consult your manual to find the reference mark on the crankshaft pulley.

- Axial Play Measurement:

- Use a magnetic dial gauge to measure axial movement in the crankshaft.

- Place the dial gauge so that its tip touches the end of the shaft.

- Rotate the crankshaft while checking the end play.

- Comparison with Specifications:

- Consult the manual for the exact end play specifications for the SAA6D125E-5 motor.

- The axial play should be in the range 0.14 – 0.315 mm.

- Registration and Document

- Record the measured values and any adjustments made on a recording sheet.

At TaopParts, each Komatsu engine goes through a rigorous verification process before being offered for sale. Mechanics not only perform axial adjustment, but also perform compression tests and other evaluations to ensure the engine is in perfect condition.

At Taopparts, we are committed to offering the highest quality spare parts and services so that our customers can operate with maximum efficiency and peace of mind.

Contact us for all your spare parts needs!

Do you need spare parts for your heavy machinery? Do not look any further. Contact Taopparts and we will provide you with the original spare parts you need to keep your machine running at peak performance.

Direct contact form