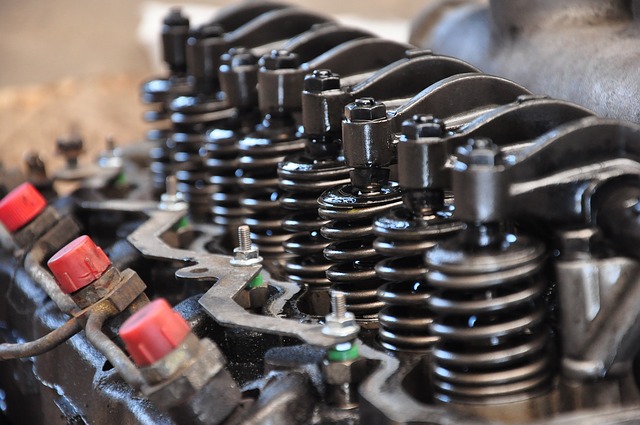

Any component with moving parts has a limited life cycle.

A construction machine owner should consider a well-planned spare parts system having the right spare parts. Having parts on hand offers a greater chance of eliminating unwanted downtime.

When the machine stops, the losses are multiple, such as employee inactivity, lost of contracts and orders, just to name a few.

It should not be overlooked that in the event that the machine stops due to a breakdown, the inability to have the correct replacement parts can lead to higher costs. For example such as the additional costs of requesting a fast delivery or the safety risk by implementing an improper repair to try to get the machine working again without the proper replacement.

Having a basic supply of spare parts on hand can reduce the risks and problems identified above.

But how do you know which spare parts a heavy machine owner should always have available?

First, it is necessary to identify which machines have the greatest impact on production. Consequently, focusing on older machines that are no longer in production, as replacement parts can be difficult to obtain. It is very important consider when request parts, especially at short notice, and therefore forced to go to the non–genuine parts market of usually poor quality.

Therefore, the objective of spare parts management should be to ensure the lowest possible overall cost, both in economic terms and in terms of productivity.

Spare parts management is a determining factor for better machine efficiency.

Maintenance of machines and organization of spare parts

Routine maintenance implies the need to organize an efficient system of available spare parts. An understanding of which cannot be dispensed whit.

For scheduled maintenance, on the other hand, spare parts must be requested within a specified period. For these, it is useless to manage the warehouse, it is rather useful to know the life cycle of each important component for the functionality of the machine.

What can the maintenance manager do to keep everything under control?

First, you must generate consumption statistics and then maintain a close collaboration with the suppliers of the parts to ensure their availability with acceptable delivery times. In addition, you must constantly communicate with maintenance technicians to know the status of machines in real time and classify spare parts according to their strategic importance.

Therefore, it is advisable to always have the so-called critical spare parts available, that is, those that reduce machine downtime due to breakdowns.

It is understandable that a company does not have the financial availability to buy, for example, a transmission or an engine and keep them in stock. But a machine which doesn’t work cannot be afforded.

To overcome these problems, you can contact Taop Parts. We have thousands of spare parts available for machines such as wheel loaders, excavators, dump truck, bulldozers, backhoe, loaders etc.

Taop Parts offers recycled, original, verified and reliable spare parts that save money for the machine owner, but above all it gives you the opportunity to have your own warehouse for spare parts, especially for critical ones.

Links of interest: