The hydraulic system is a vital component in earthmoving and mining machines, as it utilizes special fluids, usually hydraulic oil, that are under pressure.

This pressure, generated by the fluid, is essential to transmit the required power and enable the efficient operation of various components in the machines. In this way, it enables the control of actions and other crucial movements in the equipment’s operation.

Components of the hydraulic system

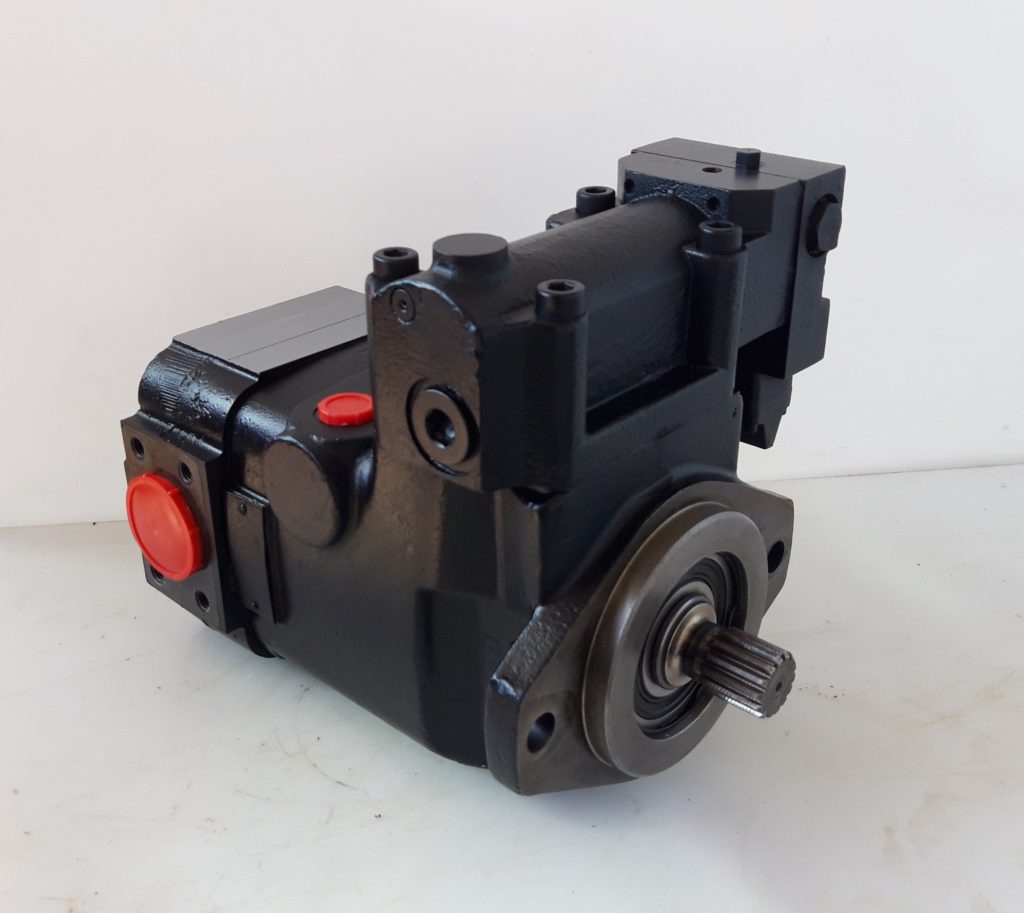

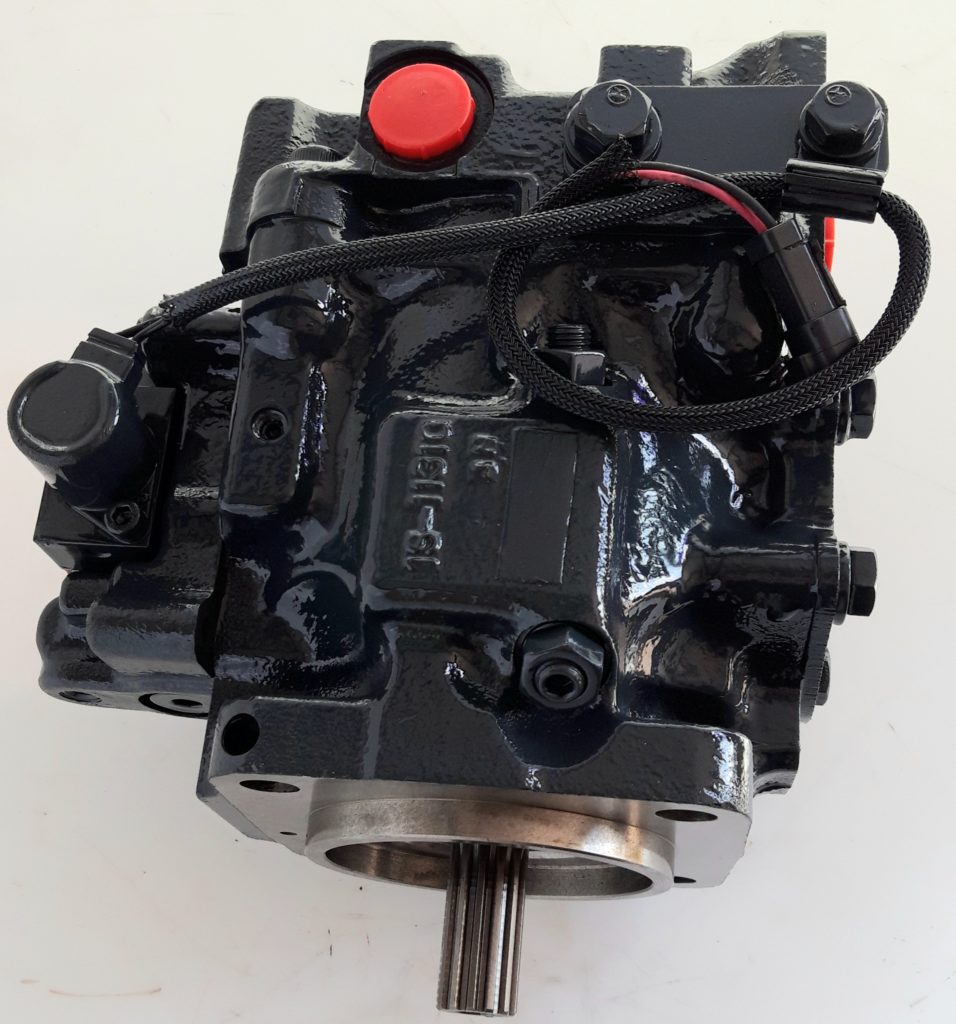

Hydraulic pump: Converts mechanical energy into hydraulic energy, generating hydraulic flow that drives the operation of the components.

Hydraulic valves: Control direction, pressure, and flow, enabling precise movement of actuators.

Hydraulic cylinders: Transform hydraulic fluid energy into linear motion, driving lifting, pushing, and pulling actions. Among the top sellers at TAOP PARTS are:

Lift cylinder: Allows the movement of the boom and generates the force needed for lifting loads.

Steering cylinder: Enables control and change of the machine’s direction.

Boom cylinder: Provides lifting and tilting motion in heavy machinery, such as excavators, for excavation and loading tasks.

Bucket cylinder: Facilitates the movement of the bucket or other attachments.

Hydraulic motors: They are responsible for converting hydraulic oil into circular motion, enabling the operation of elements such as wheels and tracks. In this way, the hydraulic system drives essential movements for the machine’s mobility and operation.

Hydraulic filters: Maintain fluid cleanliness, protecting the system components from potential damage caused by particles and contaminants.

Accumulators: Store hydraulic energy and release it when a temporary increase in pressure or flow is needed.

At TAOP PARTS, we offer all the hydraulic system spare parts, as well as a large stock of its main component, the hydraulic pump.

The hydraulic pump in Komatsu and Volvo machinery

What is it?

The hydraulic pump is a device that converts mechanical energy into hydraulic energy, generating the necessary fluid flow that drives the operation of the hydraulic system.

Types

Gear pumps

They are simple and economical, suitable for low-pressure and low-flow applications.

Axial piston pumps

Composed of multiple pistons or plungers (usually six or eight), they can handle pressures of around 380 bar. They offer higher efficiency and pressure capacity, making them ideal for demanding applications.

There are 2 types:

- Variable displacement: With the same speed, the hydraulic fluid flow can vary.

- Fixed displacement: Depending on the speed, the flow varies. Higher speed results in higher flow, and vice versa.

Vane pumps

Commonly used for fuel and/or oil transfer. They do not generate high pressure but provide a good flow rate.

Gear pumps

Composed of two gears, they have a constant flow rate. The flow rate increases with higher revolutions. They operate at a pressure of approximately 250kg.

How does a hydraulic pump work?

Typically, the hydraulic pump takes in fluid at low pressure and sends it out at high pressure, creating a continuous flow that activates the entire hydraulic system of the machine, including cylinders, main valves, hydraulic distributors, etc.

It has an inlet or suction port and a main pressure outlet (PP).

On the other hand, variable displacement piston pumps work differently, as they act by internal signal to vary the flow.

Our most popular pump models

Here are the models that our best-selling pumps fit:

Komatsu

708-1S-00230 for wheel loaders like WA470-5, WA480-5, and WA380-5.

708-1S-00940 for wheel loaders like WA470-6, WA430-6 and WA380-6.

15068597 for wheel loaders like L220D, L220E, L180E and L150E.

11709023 for wheel loaders like L220D, L150E and L180E.

In summary, the hydraulic system is a crucial component in earthmoving and mining machinery, with hydraulic pumps playing a vital role in its operation by generating the necessary hydraulic flow.

At TAOP PARTS, we understand the importance of supplying high-quality components for hydraulic systems. We offer a wide range of parts and spare parts for Komatsu and Volvo hydraulic systems. We work to ensure our customers’ machines perform at their best while promoting environmental protection and circular economy by giving our spare parts a second life.

Feel free to contact us!

TAOP PARTS

info@taopparts.com