In this article we will give you some tips on how to evaluate recycled spare parts based on technical information and photos. Continue reading Tips for buying recycled spare parts for heavy machinery

Category: Tip/advice

Advice about machinery world

Maximize production with implement maintenance

To maximize the performance of any machine, it is very important to take care of your tools. It should be noted that attachments affect the longevity, productivity, fuel consumption and maintenance costs of your equipment. Continue reading Maximize production with implement maintenance

Continue reading Maximize production with implement maintenance

Buying a new machine or thinking about alternative solutions like leasing, renting or repairing?

When the machine used for earthmoving breaks down, what are the alternative solutions that the owner has?

Buying new construction machinery certainly has its advantages if you have the right budget.

When the budget is limited, you can repair the machine and, in the meantime, you can opt for a rental option. Repair can be done with new or recycled spare parts.

Many users do not like the idea of replacing their old machine with a new one, both for economic reasons and for reasons of difficulty in learning new technologies. If the operator uses the machine well and is productive, a repair is a good solution.

Some owners, for example, would choose to repair any component with the goal of maximizing the overall life expectancy of their machine. Continue reading Buying a new machine or thinking about alternative solutions like leasing, renting or repairing?

Online shopping in the time of covid-19: considerations and advice

Many construction machine owners may be concerned about purchasing spare parts during COVID -19. The need to avoid contact, as well as various travel restrictions, can make shopping nearly impossible.

These reasons, combined with the need to save, lead the owner of heavy machinery to seek practical and convenient solutions. Even before the pandemic, used parts and equipment were bought online, but from now on this type of transaction will increasingly become the norm. Buyers will choose to buy from companies that have products with a high value and a quick and easy buying process.

In fact, the recent COVID-19 outbreak has changed the way we interact with customers. In our case, we received visits from many clients, national and international, who came to “know personally” our company. In this situation, all this has become impossible, so we have implemented a series of strategies to share online as much information as possible about our business and our company.

Buying spare parts for excavators, loaders, backhoe loaders, bulldozers, dump trucks etc., is not like buying a book or a mobile phone. It is necessary for the buyer to know exactly what he needs and, if he does not know, to provide all the technical information to the seller.

In recent years (source Oberlo.com) online shopping has increased by more than 150% and there has been a significant growth, especially in 2020. This has made it possible for online scams to grow too.

In the next paragraph we will give you some useful tips to buy online and avoid scams. Continue reading Online shopping in the time of covid-19: considerations and advice

Increase machine productivity and efficiency through spare parts management

Any component with moving parts has a limited life cycle.

A construction machine owner should consider a well-planned spare parts system having the right spare parts. Having parts on hand offers a greater chance of eliminating unwanted downtime.

When the machine stops, the losses are multiple, such as employee inactivity, lost of contracts and orders, just to name a few.

It should not be overlooked that in the event that the machine stops due to a breakdown, the inability to have the correct replacement parts can lead to higher costs. For example such as the additional costs of requesting a fast delivery or the safety risk by implementing an improper repair to try to get the machine working again without the proper replacement.

Having a basic supply of spare parts on hand can reduce the risks and problems identified above.

But how do you know which spare parts a heavy machine owner should always have available?

First, it is necessary to identify which machines have the greatest impact on production. Consequently, focusing on older machines that are no longer in production, as replacement parts can be difficult to obtain. It is very important consider when request parts, especially at short notice, and therefore forced to go to the non–genuine parts market of usually poor quality.

Therefore, the objective of spare parts management should be to ensure the lowest possible overall cost, both in economic terms and in terms of productivity.

Spare parts management is a determining factor for better machine efficiency.

Maintenance of machines and organization of spare parts

Routine maintenance implies the need to organize an efficient system of available spare parts. An understanding of which cannot be dispensed whit.

For scheduled maintenance, on the other hand, spare parts must be requested within a specified period. For these, it is useless to manage the warehouse, it is rather useful to know the life cycle of each important component for the functionality of the machine.

What can the maintenance manager do to keep everything under control?

First, you must generate consumption statistics and then maintain a close collaboration with the suppliers of the parts to ensure their availability with acceptable delivery times. In addition, you must constantly communicate with maintenance technicians to know the status of machines in real time and classify spare parts according to their strategic importance.

Therefore, it is advisable to always have the so-called critical spare parts available, that is, those that reduce machine downtime due to breakdowns.

It is understandable that a company does not have the financial availability to buy, for example, a transmission or an engine and keep them in stock. But a machine which doesn’t work cannot be afforded.

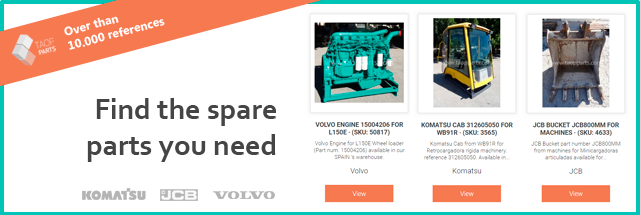

To overcome these problems, you can contact Taop Parts. We have thousands of spare parts available for machines such as wheel loaders, excavators, dump truck, bulldozers, backhoe, loaders etc.

Taop Parts offers recycled, original, verified and reliable spare parts that save money for the machine owner, but above all it gives you the opportunity to have your own warehouse for spare parts, especially for critical ones.

Links of interest:

Tires or chains?

Today we will treat with a very important topic concerning the difference between wheeled and crawler machines.

Let’s start with the first statement: earthmoving machines have wheeled and crawler versions and various factors come into play when it comes to choosing between them. These are factors related to the type of work to perform, the type of surface on which to carry it out, the load capacity, etc. Continue reading Tires or chains?

Continue reading Tires or chains?

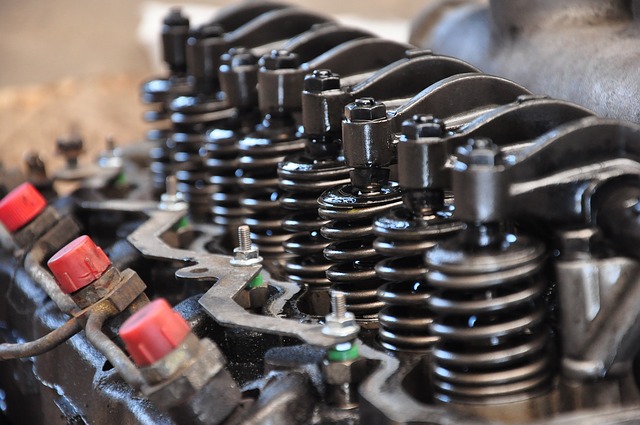

The engine: the element that converts power into hydraulic force

The engine represents one of the most important elements of excavators, loaders, dump truck, bulldozers, backhoe loaders and mini excavators.

Obviously, each type of machine will have a specific engine to adapt to the size and capacity of each individual machine.

Taop Parts, leader of the sale of original re-usable spare parts sector, checks the functioning of each engine before dismantling, certifying its correct functionality. As mentioned, each machine has a different type of engine. Let’s see what the characteristics are. Continue reading The engine: the element that converts power into hydraulic force

The cabin: the heart of the earth moving machines

Excavators, wheel loader, backhoe loaders, bulldozers, etc. lift very heavy materials during excavations and land handling in general.

These operations are carried out through the tools available to the operator such as the bucket which, thanks to the arm and the movement of the cylinder, carries out the excavations.

The operator activates the tools inside the cabin and it is made up of a series of elements and represents its control station.

Continue reading The cabin: the heart of the earth moving machines

Hydraulic cylinder: types and operating

Taop Parts offers hydraulic cylinders recovered from original machines, which have been tested and are ready to be installed.

Hydraulic cylinders are important components in earth-moving machines, such as excavators and wheel loaders, as they transform hydraulic force into linear movement, by facilitating the lifting and moving of heavy materials.

The cylinder works thanks to the hydraulic system, consisting of pumps, pipes and hydraulic fluid.

A hydraulic cylinder is a tube closed at one end with a rod that moves inside. Inside the cylinder we find a piston. The piston separates the internal side of the cylinder from the external one. The fluid moves to both sides of the cylinder to extend or retract the rod.

Hydraulic cylinders can push, pull and lift different types of loads with different weights and sizes.

Tips on when to replace the components of heavy machines

Heavy machines such as wheel loader, backhoe loader, dump truck, bulldozers, etc., are essential in a construction, public works company, in a quarry or mine and they should be used correctly, it must be handled by skilled personnel and periodically checked.

It is very important to know the operation of each component, to carry out the appropriate tests.

Continue reading Tips on when to replace the components of heavy machines

Continue reading Tips on when to replace the components of heavy machines