We explore the main powertrain components in a loader, using the Volvo L120F as an example. To go even deeper, let’s take a look at some additional aspects and expand with examples from other loaders:

Axle: The Base of the Support

The axles of a Volvo L120F loader are crucial components that ensure the mobility, stability and power of this robust machine. Designed and manufactured to the highest quality standards, these axles play a fundamental role in the daily performance of the loader.

Main functions of the axes:

- Weight support: The axles support the total weight of the loader, including the machine itself, the load in the bucket and any additional accessories.

- Power Transmission: The axles transmit power from the engine to the wheels, allowing the loader to move forward, backward, twist and turn on its own axis.

- Shock Absorption: The axles absorb impacts and vibrations from the ground, protecting the machine and operator from damage.

- Steering: The axles allow the loader to turn and maneuver with precision.

In the photo below you can see some axles of a VOLVO L120F loader

Differentials: Adapting to Every Terrain

The differential is a crucial part of the machine’s transmission system. Its main function is to allow the tyres to rotate at different speeds when the machine is turning or cornering. This helps maintain traction and prevents excessive wheel slip.

Differential components:

- Crown and pinion gears: These gears are located inside the differential. The ring gear is a large sprocket that connects to the drive shaft, while the pinion is connected to the output shaft to the wheels. Together, they allow the distribution of power between the wheels.

- Satellites and planetaries: Satellites are small gears that rotate around planetary gears. The planetaries are connected to the pinion and the ring gear. When one tyre spins faster than the other (for example, in a curve), the satellites allow the planetary gears to move, adjusting the speed of the wheels.

- Differential housing: It is the structure that contains all the components mentioned above. It also provides support and protection.

Functioning:

When the machine turns, the differential allows the outside wheels to spin faster than the inside wheels. This prevents slipping and improves traction. If one wheel loses traction (for example, on slippery terrain), the differential redirects power to the wheel with the best grip.

In short, the differential is essential for the stability, handling and traction of the Volvo L120F. Without it, the wheels would not be able to rotate independently, making operation on varied terrain difficult.

Types of differentials

- Open Differential: This is the most common type of differential and allows the wheels to spin at different speeds. However, it can allow one wheel to spin faster than the others, which can lead to uneven tire wear and loss of traction.

- Locking Differential: This type of differential locks the wheels to rotate at the same speed, which improves traction on difficult terrain. However, it should not be used on hard surfaces as it may damage the drivetrain.

- Limited Slip Differential: This type of differential combines the features of open and locked differentials. It allows the wheels to spin at different speeds up to a point, but then locks up when more traction is needed.

In the photo you can see a differential 11103282 of a Volvo L120F loader

A Crucial Shipment to Mozambique

Recently, two axles, one front and one rear, along with two differentials, were shipped from Valencia, Spain, to Mozambique. These components will be used to repair or replace worn parts on a Volvo L120F machine operating in that country. The shipment of these critical parts ensures that the machine can continue to operate efficiently and safely, contributing to the development and progress of Mozambique.

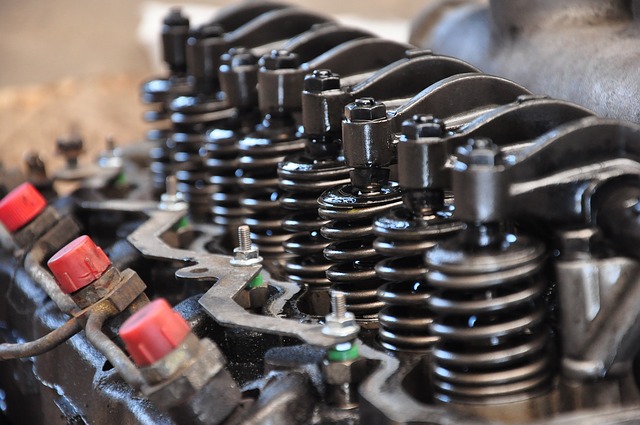

At Taopparts, our expert mechanics carefully inspect each part before shipping it to our customers. In this case, one of our technicians is meticulously checking an axle on a Volvo L120F loader.

This exhaustive review ensures that the axle meets the highest standards of quality and performance, ensuring that the customer receives a reliable and long-lasting part for their work equipment.

At Taopparts, we are committed to offering the highest quality spare parts and services so that our customers can operate with maximum efficiency and peace of mind.

Contact us for all your spare parts needs!

Do you need spare parts for your heavy machinery? don´t look any further. Contact Taopparts and we will provide you with the original spare parts you need to keep your machine running at peak performance.

- Direct contact form

+34 689 791 639

+34 689 791 639 +34 96 151 96 50

+34 96 151 96 50 info@taopparts.com

info@taopparts.com