Heavy machines such as wheel loader, backhoe loader, dump truck, bulldozers, etc., are essential in a construction, public works company, in a quarry or mine and they should be used correctly, it must be handled by skilled personnel and periodically checked.

It is very important to know the operation of each component, to carry out the appropriate tests.

We have dealt with the issue of maintenance and the good practices that must be implemented in different articles already, to always have the machines in perfect condition.

We have dealt with the issue of maintenance and the good practices that must be implemented in different articles already, to always have the machines in perfect condition.

How to detect problems in the fluid system of wheel loaders, bulldozers, dumpers and excavators

Fuel consumption on wheel loaders, excavators, bulldozers, dumpers: technology and saving advice

Depending on the type of component that needs to be replaced, a used original spare part may be ideal over a new part, for two main reasons: immediate availability and savings. Generally, the owner of a machine should know where to find the spare parts that most interest him and make small repairs. This will prevent something from being damaged, and then must carry out more complex and expensive repairs.

Table of Contents

Components of a machine and recommendations for its replacement

Air filter

The replacement of this component is not based on its use or time, but on its retention: when it is dirty, it must be replaced. This operation allows the life of the engine to be extended, emissions to be reduced and fuel efficiency to be increased. A dirty filter can reduce engine performance and damage it.

Battery

Diesel engines typically have two batteries to power the starter system and power the electrical components of excavators, shovels, dump trucks, etc.

The battery lasts for 4/5 years, but is replaced when it does not charge properly.

Injector

The injectors provide the fuel to the engine of a machine. If the injector is clogged, you will not be able to supply fuel to the engine.

Tubes

Tubes need to be replaced about every 4 years, but if machines are used daily, then the replacement should be faster. The tubes serve to transmit fluids to the engine, power steering, hydraulic system and attachments. The tubes must not have cracks or bubbles. Tubes are one of the most worn parts.

Hydraulic system filters

The main function of these types of filters is to purify the fluid from the entire hydraulic system. When it deteriorates, it must be replaced because otherwise the machine can damage the hydraulic system.

Chains

After moving, the chains wear out over time. The typical wear is crushing which is very dangerous for everyone around the machine. Frequent checking of these components will prevent damage and accidents.

Attachments

Attachments/quick coupler cause many problems and are very dangerous. These bends when objects are not balanced enough and break when under pressure. After each application they must be controlled and not present cracks.

Use the proper components

Trained operators know the optimal state of each component before using it. This means that maintenance operations must be carried out daily, either for safety or for the correct operation of the machine.

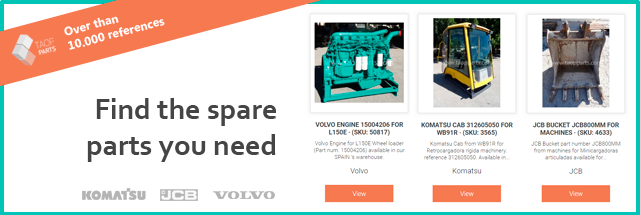

Taop Parts recommends using original spare parts, as they are perfectly adapted to the machines. In addition, it offers the use of used spare parts with immediate availability, savings on repairs and respect for the environment.

Links of interests;

Hello, after reading this awesome piece of writing i am as well delighted to share my familiarity here with colleagues.

I liked that you pointed out that it would be smart to make sure that the parts you are getting will work well in your machine. It does seem like you would want to check the serial numbers of the parts to make sure that they match. Personally, I would want to get a professional to help me find any replacement parts for heavy machinery.