Today we will treat with a very important topic concerning the difference between wheeled and crawler machines.

Let’s start with the first statement: earthmoving machines have wheeled and crawler versions and various factors come into play when it comes to choosing between them. These are factors related to the type of work to perform, the type of surface on which to carry it out, the load capacity, etc.

Table of Contents

Crawler and wheeled machines: their use.

A crawler machine is almost always the preferred choice on construction sites or for landscaping work as they provide more traction and better conservation. Furthermore, if you think, for example, of wet ground, a machine with tires should wait for them to dry, otherwise it may run aground. This does not happen with crawler machines, as they operate with less pressure on the ground.

And that is why they should be preferred over tires when used in mountain terrain. Obviously, when it comes to asphalted or works areas that require a certain speed of movement then the choice of vehicles with tires is to be preferred.

As far as load capacity is concerned, a crawler machine can carry 30% more than a wheeled machine, due to its heavier bearing system and greater stability. In fact, on a crawler machine it is possible to mount a dipper with greater load capacity; this is especially important for those who work with hard materials.

Differences in the controls of wheeled and crawler machines

Wheeled machine

Steering wheel: controls steering during travel. Equipped with two levers. Lever to the left of the steering wheel for gear change and for the horn; lever to the right of the steering wheel activates the lights and direction devices.

Pedals: left pedal for the main service brake; right pedal for the accelerator.

Console: allows the control levers of the equipment to be operated.

Crawler machine

Steering wheel: it has no steering wheel but two control levers on the sides of the seat. The left lever controls the translation of the machine, while the right lever activates the tools placed on the quick coupler.

Pedals : there are 3 pedals placed in front of the operator. Left pedal operates the left chain; right pedal operates the right chain. Centre pedal activates the brake.

Console: it allows the vehicle to be moved back and forth with different travel speeds.

Wheeled and crawler machines: maintenance

The manufacturer will indicate, the types and frequencies of inspections and maintenance necessary for safety reasons in the operating instructions. Let’s see which are the ordinary maintenance operations in the two systems analysed.

Crawler systems

Regular maintenance is essential to maintain the reliability of crawler systems.

It is important that the chain are maintained according to the manufacturer’s directions. The operations to be carried out in principle are:

- Carry out maintenance on flat and resistant surface;

- Verify that the crawler system is firmly and securely supported when working under the crawler systems;

- Remove any traces of grease, oil or rubble;

- Repair all damages and immediately replace worn or broken parts;

- Check for any oil leaks or damage to hydraulic pipes.

- Use only lubricants specified by the manufacturer. Do not combine different brands or types of lubricants.

- Only use original parts, including recycled ones.

- Dispose of lubricants properly.

Wheeled systems

Control of the wear condition of the tires and regular pressure of the tires in of great importance for the stability and safe operation of the machine is. In relation to the type of work performed, as defined in the manual of the manufacturer of the mechanical vehicle.

The tires are specially designed for the type of machine so if one is worn or damaged it must be replaced with another of the same size and the tread model must be the same as the others. The mounting of tires of different sizes and characteristics on both sides of the machine can lead to premature wear, loss of power and excessive effort in the transmission. In fact, in the presence of a deteriorated tire, it may burst and / or detach its supports. Check for external damage such as cuts.

Final considerations

Crawler machines are the most versatile on a construction site. They save time and money as they are able to carry out a series of operations such as land reclamation, excavation, backfilling, levelling, transport, spreading of materials, all this even if working on a sloping terrain.

The wheeled machines, on the other hand, are more used in quarries, mines and guarantee durability for multiple life cycles.

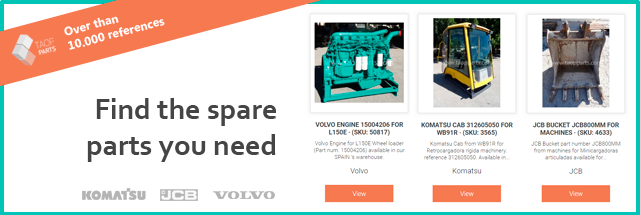

Taop Parts reminds you that, be it your wheeled or crawler machines, it has thousands of original spare parts available, reusable, verified and ready to be mounted.

Links of interest: