Heatwaves pose significant challenges, not only for people but also for machinery operating in construction sites, quarries, mines, and, in general, outdoor workplaces.

High temperatures can have a detrimental impact on the performance, lifespan, and integrity of all heavy machinery, including excavators, wheel loaders, rigid and articulated dump trucks, and bulldozers. Let’s examine the risks that heatwaves present and discuss essential tips on how to properly protect and maintain this equipment in challenging weather conditions.

Table of Contents

Understanding the Risks

Extreme heat can trigger a series of issues in machinery, affecting their operation and leading to costly breakdowns. Let’s examine some of these risks:

Engine Overheating

High temperatures can strain the cooling system. Excessive heat can push the engine to operate at dangerous temperatures, potentially resulting in severe damage.

Accelerated Wear and Tear

Extreme heat accelerates the wear of mechanical parts, electrical components, and seals, which in turn can reduce the overall equipment lifespan.

Decreased Performance

Machines may become less efficient in extreme heat, impacting productivity and increasing operational costs.

Preventive Maintenance and Cleaning

Comprehensive preventive maintenance before and during heatwaves is essential to keep the machinery in optimal condition. Here are some key measures:

- Cooling System Inspection

Always ensure that radiators, coolers and ventilation systems are clean and free from obstructions. It’s crucial that fans work properly to ensure adequate cooling.

-

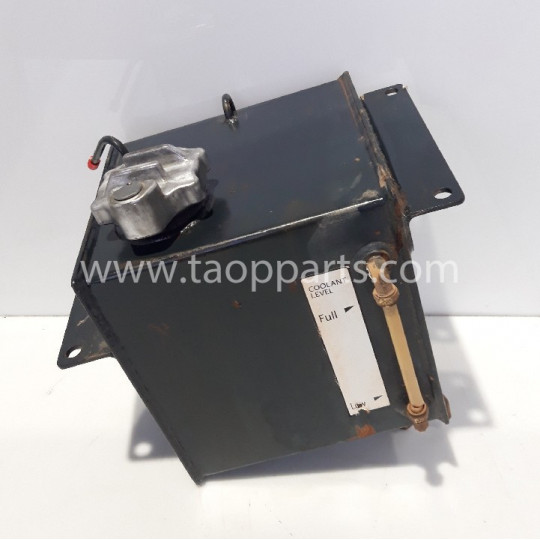

Fluid Control

Maintain the proper levels of coolant and lubricants in the tanks according to the manufacturer’s specifications. High-quality fluids are essential to protect the machinery from high temperatures and friction.

-

Air Conditioning System (AC)

We must ensure that the air conditioning system is functioning properly to provide the operator with a more comfortable and safe environment, which can also help maintain focus and reduce fatigue. To achieve this, we will check the refrigerant level, clean filters, inspect hoses and connections, and remember to perform periodic system tests before shifts where the machine will be exposed to high temperatures.

Constant Temperature Monitoring

Implementing temperature monitoring systems can be vital to detect overheating issues in a timely manner and take preventive measures. Infrared thermometers and temperature sensors can provide real-time readings to identify potential hotspots.

Adjustment or Replacement of Components

An essential aspect of maintenance is regular inspection of the machine’s key components for signs of wear. We must replace and adjust worn-out parts to prevent unexpected breakdowns that may occur during work in extreme conditions, such as the high temperatures that some work sites can experience during the summer months.

Smart Scheduling

Planning heavy machinery operations based on weather forecasts can significantly reduce stress on the machine. Avoiding operation during the hottest hours of the day and performing the most intensive tasks in the early morning or late afternoon, when temperatures are lower, is beneficial.

Protection and Shelter

When the machines are not in use, it is advisable to keep them in shaded areas or under covers to protect them from direct sunlight. This can help reduce exposure to high temperatures and prevent damage to sensitive components, such as the electrical system, which can be vulnerable to overheating, leading to significant wear on the insulation materials of the wiring.

Operator Training

While we’ve primarily focused on machines, we cannot overlook the role of the operator. Training the operator on how to recognize signs of overheating and how to take corrective actions is essential. Operators should be attentive to warning signs and know when to stop the machine to prevent further damage.

Heat-Sensitive Components

Some components most sensitive to high temperatures in the summer are those subject to constant friction, involved in cooling processes, or containing materials that can degrade in extreme heat. For example:

- Belts

Transmission belts, like alternator belts and fan belts, are susceptible to hardening, cracking, or breaking due to excessive heat. If they’re worn out, they can result in system failures and energy loss.

-

Hoses or Tubes

Since they transport coolant, oils, and hydraulic fluids, hoses and tubes can become more susceptible to leaks and ruptures when exposed to high temperatures. If they are weak or damaged, they can cause a loss of essential fluids necessary for proper functioning.

-

Thermostats

Thermostats regulate the engine temperature by controlling the flow of coolant. If they fail due to extreme heat, they can cause overheating or inadequate cooling of the engine.

- Seals and Gaskets

High temperatures can cause seals and gaskets to degrade, leading to leaks and contamination of critical fluids.

- Oils and Lubricants

If of low quality, their viscosity can be affected under extreme heat, which impacts their ability to properly lubricate and protect moving parts.

- Electrical Components

Some electrical components, such as relays, switches, cables, and connections, may experience overheating due to high temperatures, which could result in malfunction or failure.

-

Fans

While designed to assist in the cooling system, fans can also be affected by high temperatures. If fans do not operate properly or if they become obstructed, the cooling system may not be as efficient, increasing the risk of overheating.

In conclusion

Proper protection and maintenance of earthmoving and mining machinery during heatwaves are essential to ensure the safety, efficiency, and longevity of the equipment.

By understanding the risks and implementing preventive measures such as regular maintenance, temperature monitoring, and smart planning, we can minimize the negative impact of extreme heat. Let’s remember that these investments in care and prevention not only safeguard our assets but also protect the workers operating these machines, ensuring a safer and more productive work environment in any climatic conditions.

You can reach us at:

info@taopparts.com

www.TaopPart.com